Peanut Butter Production Line

Diana /

Diana /  Jun 30, 2017

Jun 30, 2017

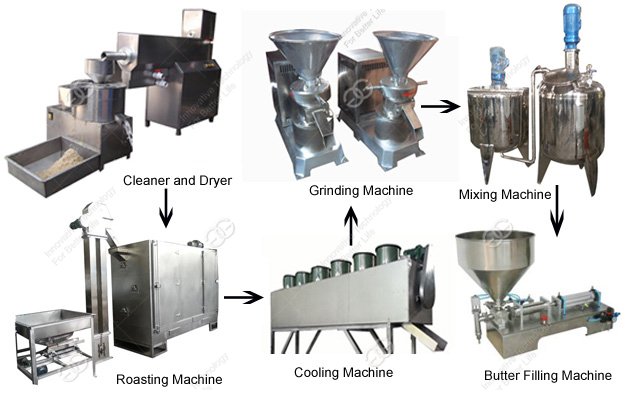

Peanut butter production line process: Raw materials - Stone removing and roguing - Roasting - Cooling - Peeling - Selecting - Coarse grinding - Mixing - Fine grinding - Cooling - Degassing - Filling.

Peanut butter production line main equipment: Roasting oven, cooling zone, peeling machine, the picking zone, coarse grinding machine, superfine grinding, condensing unit, tank, filling machine. (For the above required equipment, the company has production and sales)

Roasting oven: This oven is used to roast peanuts.

Cooling belt: Use the fan out of the heat principle, cooling the roasted peanuts.

Peeling machine: Peel the peanuts after drying and baking, skin and peanuts seperate automatically in the process of peeling, ensuring the quality of the peanut after peeling.

Selecting belt: Unqualified peanuts and food residue will be picked out.

Coarse grinding machine: First grinding the peanuts.

Fine grinding machine: The peanuts need further grinding after the rough grinding, processing fineness further improved.

Peanut butter and cooling condensing machine: Cooling the peanut butter after grinding.

Degassing tank: Peanut butter needs to degas before filling.

Its characteristics are flow operation, high mechanization degree, good reliability, full enclosed production, pollution-free. Production of peanut butter meets export standards.

- Previous: Prev:General Introduction For Peanut Butter Machine

- Next: Next:Fresh Noodles Maker Sold To Turkey

Message

Message