Features

Features

The stainless steel macaroni production line uses wheat flour, corn starch, potato starch as the main raw material, using a unique compression molding process. product modeling with natural realistic, delicate texture. The production line has reasonable design, stable and high degree of automation; mainframe adopts advanced frequency conversion technology, energy efficient. The macaroni making machine can make different types of products, such as spiral, shells, tubes, sub-spiral, circle, wave, etc.

This industrial macaroni production line consists of six parts: flour mixing machine, spiral hoister, extruder machine, cutting machine, hoister, dryer.

〇 Flour mixing machine is used to mix raw materials, auxiliary materials, and water, moderate speed.

〇 The spiral hoister mainly used for feeding the raw material to the main feed inlet.

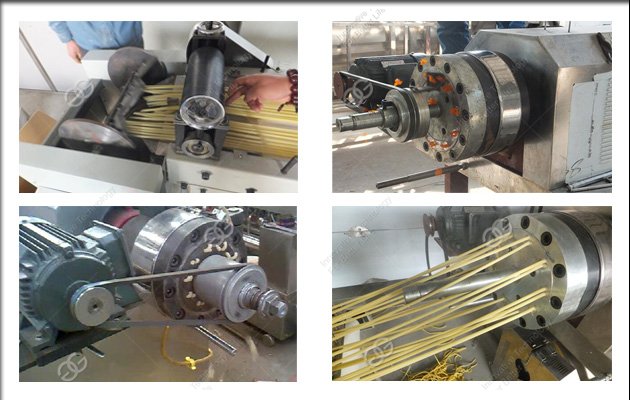

〇 Extruder machine consists of feeding system, extruding system, the biopsy system, heating system, transmission, cooling system, control system. Adopts advanced screw extrusion technology, use low temperature and high pressure curing the material forming one time.

〇 Cutting machine: this machine can cut macaroni into different shapes by changing molds.

〇 Finally, the hoist will transport the finished product to the drying machine for drying.

Macaroni Production Line Features:

1. The macaroni making machine with stable performance, easy operation and easy maintenance.

2. Automatic temperature control of the dryer, guaranteed drying quality, humidity can be adjusted according to different products.

3. Vacuum flour mixing technology are used to improve the flexibility of the finished product and the uniformity of water content to adapt to different quality flours.

4. The extrusion molding part of the macaroni production line is compact in form, large in output, extrusion die, reasonable pressure design, good quality of macaroni finished product, neat appearance, uniform color and smooth surface.

5. After drying, the macaroni is air-cooled by air filtration device, so that the finished product is not polluted by air, and the discharge material adopts the vibration discharge form, which can screen out unqualified finished products and improve the qualified rate of finished products.

This industrial macaroni production line consists of six parts: flour mixing machine, spiral hoister, extruder machine, cutting machine, hoister, dryer.

〇 Flour mixing machine is used to mix raw materials, auxiliary materials, and water, moderate speed.

〇 The spiral hoister mainly used for feeding the raw material to the main feed inlet.

〇 Extruder machine consists of feeding system, extruding system, the biopsy system, heating system, transmission, cooling system, control system. Adopts advanced screw extrusion technology, use low temperature and high pressure curing the material forming one time.

〇 Cutting machine: this machine can cut macaroni into different shapes by changing molds.

〇 Finally, the hoist will transport the finished product to the drying machine for drying.

Macaroni Production Line Features:

1. The macaroni making machine with stable performance, easy operation and easy maintenance.

2. Automatic temperature control of the dryer, guaranteed drying quality, humidity can be adjusted according to different products.

3. Vacuum flour mixing technology are used to improve the flexibility of the finished product and the uniformity of water content to adapt to different quality flours.

4. The extrusion molding part of the macaroni production line is compact in form, large in output, extrusion die, reasonable pressure design, good quality of macaroni finished product, neat appearance, uniform color and smooth surface.

5. After drying, the macaroni is air-cooled by air filtration device, so that the finished product is not polluted by air, and the discharge material adopts the vibration discharge form, which can screen out unqualified finished products and improve the qualified rate of finished products.

Technical Data

Technical Data

| Machine name | Parameter |

|

Blender (with container) |

Capacity:4 kw Real power:3kw Output:300kg/h Size:1.0*0.6*1.4m Stainless steel: 201 |

| Screw conveyor |

Capacity:0.75 kw Real power:0.5kw Output:300kg/h Size: 3.3*0.8*2.3m Stainless steel: 201 |

| Extruder(Single -screw) |

Capacity:47 kw Real power:26kw Output:100-120kg/h Size:3.1*0.9*2.0m Stainless steel: 201 |

| Cutter |

Capacity:1.5 kw Real power:1kw Size:1.2*0.9*1.3m Stainless steel: 201 |

| Hoister |

Capacity:0.4 kw Real power:0.3kw Output:300kg/h Size:2.4*0.6*1.5m Stainless steel: 201 |

| Oven |

Capacity:45kw Real power:35kw Output:250kg/h Size:5.0*1.2*1.8m Stainless steel: 201 |